A NEW GENERATION OF ROBOTS

The latest Fullwood milking technology

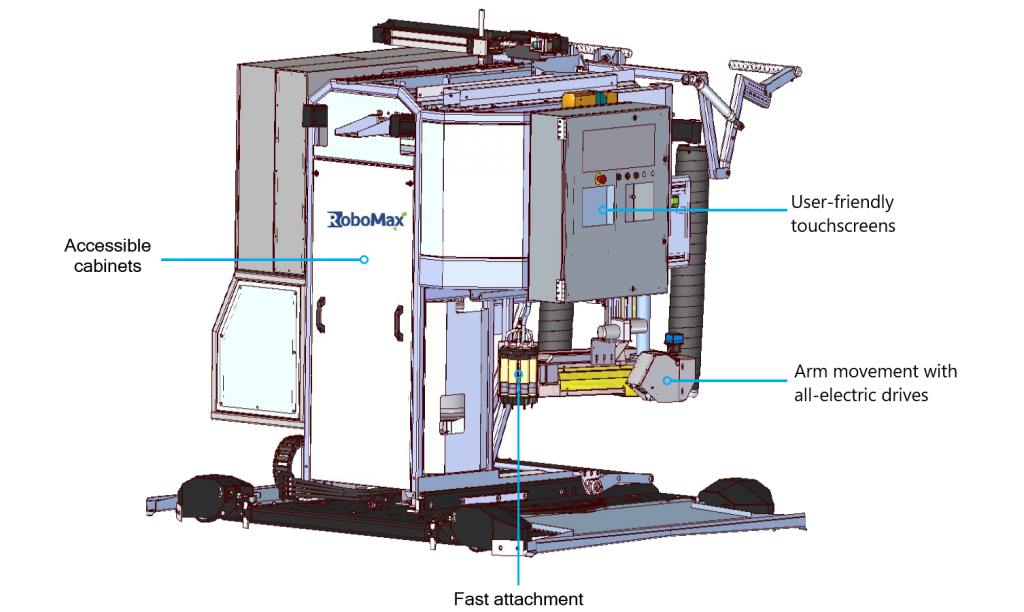

A suspended tray holds a flex cable chain supplying electricity, water and compressed air to the robot. It also connects to the pipeline sending milk to the bulk tank.

A suspended tray holds a flex cable chain supplying electricity, water and compressed air to the robot. It also connects to the pipeline sending milk to the bulk tank.

FLEXIMAX

A first touchscreen controls the FLEXIMAX software to manage the robot’s schedule and travel within the barn. A farmer can use it to select the number of milkings per day per cow (1, 2, 3 or 4).

FLEXIMAX:

A first touchscreen controls the FLEXIMAX software to manage the robot’s schedule and travel within the barn. A farmer can use it to select the number of milkings per day per cow (1, 2, 3 or 4).

HMI

A second touchscreen, the HMI (Herd Management Interface), provides a user-friendly interface to access data such as lactation curves, milk production, cleaning, etc.

HMI:

A second touchscreen, the HMI (Herd Management Interface), provides a user-friendly interface to access data such as lactation curves, milk production, cleaning, etc.

FROM TEAT TO TANK:

Combining Robomax and M2erlin technology, Milkomax offers the world’s only robotic solution allowing a dairy farmer to manage, within a single software, a herd with both tie-stall and free-stall cows! Milkomax offers a completely automated solution including the essential buffer tank.

FROM TEAT TO TANK:

Combining Robomax and M2erlin technology, Milkomax offers the world’s only robotic solution allowing a dairy farmer to manage, within a single software, a herd with both tie-stall and free-stall cows! Milkomax offers a completely automated solution including the essential buffer tank.

THE SUCCESS OF ROBOMAX IS BASED ON 3 KEY FACTORS:

1. PRODUCTIVITY

-

Accurate, reliable and fast attachment

-

Flexibility to select the number of milkings per day per cow

-

Flexibility to select milkings’ chronological order

2. MILK QUALITY

-

Best milking technique = more, high quality milk

-

Focus on cleaning and cow health

3. PROFITABILITY

-

Electric-only drives deliver energy savings

-

Reduced maintenance time and cost

-

No additional feed costs to attract cows to the robot

-

Very low animal loss linked to stalling system (few foot rot or slipping problems, no competition, etc.)